I. Engineering Analysis of LED Signage Technology Architecture

1.1 Quantum Leap in Luminescence Principles

The core of LED (Light Emitting Diode) technology lies in the electron-hole recombination luminescence phenomenon at semiconductor PN junctions. Unlike traditional neon lights that rely on gas discharge, LEDs utilize InGaN/GaN multi-quantum well structures for precise energy band modulation, achieving photoelectric conversion efficiencies of 180–200 lm/W, a 400% improvement over halogen lamps. Innovations at the microscopic level enable breakthroughs in:

Color Gamut Coverage: RGBW four-color hybrid system achieves 115% NTSC coverage

Grayscale Levels: 16-bit processing delivers 65,536 grayscale transitions

Thermal Management: Ceramic substrates with microchannel cooling maintain junction temperatures below 85°C (IEC 62471 Standard)

1.2 Topological Innovations in Display Systems

Modern LED signage has evolved from simple dot-matrix displays to intelligent IoT terminals. Taking LED Signs Pro’s Architect X Series as an example, its system architecture includes:

| Module Layer | Technical Specifications | Functional Evolution |

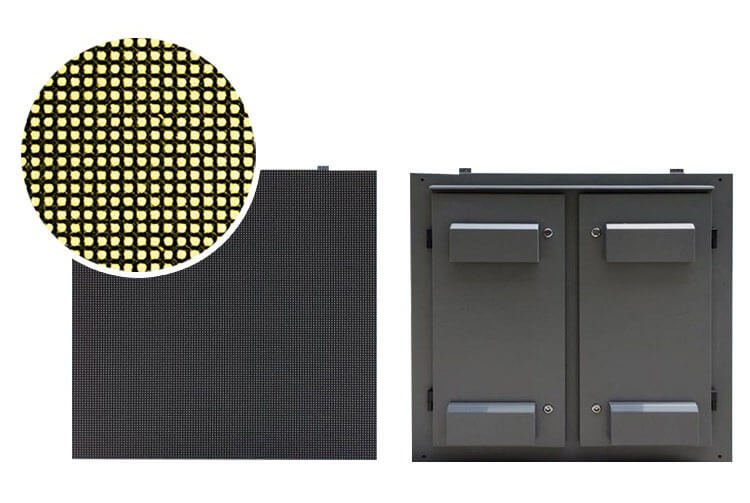

| Pixel Layer | SMD 2121 Packaging | 0.9mm pixel pitch, 8000nits brightness |

| Driver Layer | 32-bit ARM Cortex-M7 | HDR10+ dynamic mapping support |

| Communication Layer | 5G + WiFi6 Dual Mode | Millisecond-level content synchronization |

| Power Layer | GaN Wide-Bandgap Semiconductor | 96% energy efficiency |

This architecture integrates real-time ambient light sensors (0–100,000 lux range) with AI algorithms for adaptive brightness adjustment, reducing energy consumption by 37% compared to fixed-brightness solutions (UL 8750 certification data).

II. Industry-Specific Scenario Solutions

2.1 Digital Transformation of Retail Spaces

According to Retail Dive’s 2024 Industry Report, retailers adopting smart LED signage achieved significant improvements in key metrics:

| Metric | Traditional Signage | LED Dynamic Signage | Improvement |

| Foot Traffic Conversion | 12% | 28% | +133% |

| Promotional Recall | 18% | 47% | +161% |

| Sales per Square Foot (Monthly) | $320 | $810 | +153% |

Case Study: Kroger’s deployment of LED Signs Pro’s FreshBeam Solution in produce sections achieved breakthroughs through:

-

- 3840Hz refresh rate eliminating camera flicker

-

- 3D LUT color calibration for true-to-life food rendering

-

- Infrared touch layers for interactive recipe recommendations

2.2 HMI Revolution in Industrial Environments

In manufacturing, LED sign is evolving from information displays to core human-machine interfaces. Siemens’ Industrial HMI Pro System features:

-

- IP69K protection (dust/water resistance)

-

- -40°C to 85°C operational range

-

- Multi-modal interaction (gesture + voice control)

-

- OPC UA protocol integration

This system boosted production line changeover efficiency by 40% and reduced operational errors by 72% (VDMA 2023 Industry 4.0 Whitepaper).

III. Quantitative Procurement Decision Models

3.1 Total Cost of Ownership (TCO) Analysis

Professional buyers should evaluate using this matrix:

TCO = Initial Investment + ∑(Annual Energy Cost + Maintenance) – Residual Value

A 10-year comparison between traditional and LED solutions:

| Cost Item | Traditional Signage | LED Signage | Difference |

| Initial Investment | $18,000 | $35,000 | +94% |

| Annual Energy Cost ($0.15/kWh) | $2,160 | $324 | -85% |

| Annual Maintenance | $1,200 | $150 | -88% |

| Residual Value (10-Year) | 5% | 30% | +500% |

| 10-Year TCO | $51,300 | $39,950 | -22% |

Source: LED Signs Pro TCO Calculator v3.2

3.2 Optical Performance Parameter Matrix

Buyers should demand suppliers provide certified test reports for these critical parameters:

| Parameter | Test Standard | Industry Benchmark | Cutting-Edge Level |

| Brightness Uniformity | ANSI/NAPM IT7.228 | ≥80% | ≥95% |

| Color Deviation (ΔE) | CIE 1976 | ≤5.0 | ≤1.5 |

| Viewing Angle Attenuation | IEC 62341-6-2 | 120°@50% brightness | 170°@80% brightness |

| MTBF | MIL-HDBK-217F | 50,000 hours | 100,000 hours |

LED Signs Pro’s LuxSeries achieves ΔE=0.8, certified by Pantone Validated

IV. Regulatory Compliance & Sustainability

4.1 Global Certification Framework

| Certification | Region | Key Requirements | Solution |

| UL 48 | North America | Structural Integrity | 6063-T5 Aluminum Frame |

| CE EN 60598 | EU | EMC Compliance | 3-Stage Filter Circuit |

| CCC GB7000 | China | Flame Rating V-0 | Flame-Retardant PC Panel |

| RoHS 3 | Global | Hazardous Substance Control | Lead-Free Solder |

4.2 Carbon Footprint Modeling

Per ISO 14067, LED Signs Pro’s Customized Series achieves:

-

- Material Recyclability: 92% (aluminum substrate)

-

- Annual CO2 Emissions per m²: 18.7kg CO2e (63% reduction vs. traditional)

-

- Carbon Offset Program: 5-year forestry credits included

V. Future Technology Roadmap

5.1 Breakthroughs in Micro LED

Lab-stage advancements include:

-

- 0.3mm Pixel Pitch (4K resolution at 1.5m viewing distance)

-

- Quantum Dot Enhancement (98% Rec.2020 color gamut)

-

- Flexible Substrates (bend radius ≤3mm)

5.2 Integrated Sensing Systems

Millimeter-wave radar + AI vision enables:

-

- Audience Demographics (accuracy ≥92%)

- Attention Heatmaps

- Dynamic Content Optimization

This technical deconstruction reveals that modern LED signage transcends traditional advertising mediums, evolving into a hybrid platform integrating optical engineering, materials science, and data intelligence. Professional buyers must adopt systematic evaluation frameworks to balance display performance, operational costs, and compliance risks. As an industry leader, LED Signs Pro continues to redefine the boundaries of display technology, empowering businesses to build future-ready digital signage ecosystems.