Introduction: The Evolution of 3D Printed Signs in Modern Branding

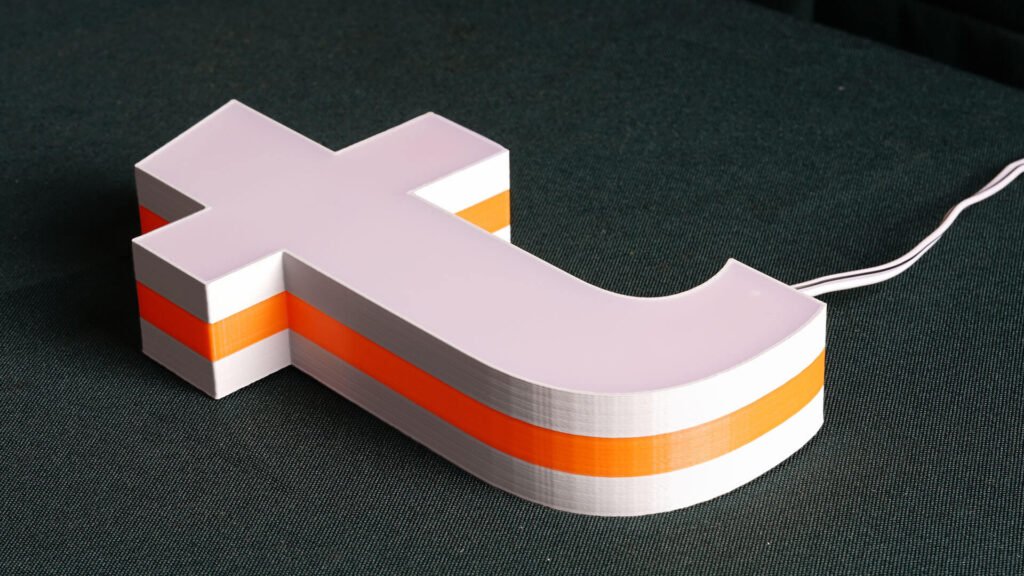

3D printed signs are revolutionizing how brands and individuals communicate visually, merging industrial-grade precision with artistic freedom. LEDSignsPro.com, a pioneer in this space, leverages advanced 3D printing and LED integration to create signage that transcends traditional limitations.

Why 3D Printed Signs Outperform Traditional Alternatives

1. Hyper-Customization: Beyond Templates

LEDSignsPro’s 3D printed signs eliminate design constraints. Using CAD-compatible files, clients can replicate complex geometries (e.g., organic curves, multi-layer textures) with a resolution of 0.1 mm. The process supports:

Size Flexibility: 5 cm to 2 m in height.

Material Blends: Acrylic-PLA hybrids for lightweight durability.

Color Mastery: 16 Pantone-matched hues, RGB gradients, and UV-reactive finishes.

2. Engineering for Real-World Demands

Weather Resistance: IP65-rated components withstand monsoons (-20°C to 80°C tolerance).

Structural Integrity: 6–10 mm acrylic bases prevent warping, while epoxy-bonded layers resist delamination.

LED Longevity: 50,000-hour lifespan (Philips SMD2835 LEDs) with <5% luminosity decay over a decade.

Technical Deep Dive: What Makes LEDSignsPro’s 3D Printed Signs Unique

1. Material Innovation

Base Materials:

Acrylic-PLA Composite: 30% lighter than pure acrylic, 2x impact resistance.

Epoxy Resin Fronts: Scratch-resistant, UV-stable gloss finish (85° gloss units).

LED Integration:

Dynamic Control: Bluetooth-enabled dimming (10%–100%) and color sequencing via the customized app.

Energy Efficiency: 2.4W/ft² consumption vs. 8.5W/ft² for traditional neon.

2. Manufacturing Process

Step 1: CAD file optimization (free design support).

Step 2: Multi-axis 3D printing (0.05 mm layer accuracy).

Step 3: LED embedding with liquid adhesive for seamless diffusion.

Step 4: IP65 stress-testing (72-hour humidity chamber).

3. Global Compliance & Safety

Certifications: CE, RoHS, FCC.

Voltage Options: DC5V/12V or Dual 110V/220V drivers with surge protection.

Fire Rating: UL94 V-0 (self-extinguishing acrylic).

Applications: Where 3D Printed Signs Deliver Maximum Impact

1. Retail & Hospitality

Case Study: A Brooklyn boutique saw a 40% foot traffic increase after installing a 3D printed “SALE” sign with pulsating RGB edges.

ROI Tip: Pair signs with QR codes linking to loyalty programs.

2. Corporate Environments

Lobby Signage: 3D printed logos with backlit branding.

Wayfinding: Color-coded directional signs (ADA-compliant fonts).

3. Events & Personal Spaces

Weddings: Floating 3D table numbers with wireless LEDs.

Home Offices: Motivational quotes in matte acrylic (reduces glare).

Head-to-Head: LEDSignsPro.com vs. Competitors

| Metric | LEDSignsPro.com | Average Competitor |

| Customization Depth | Full 3D modeling support | Pre-set templates only |

| Production Speed | 3–5 days (rush: 24 hours) | 10–14 days |

| Warranty | 3 years (parts/labor) | 1 year (parts only) |

| Price Transparency | Instant online quotes | Mandatory sales calls |

FAQs: Addressing Buyer Concerns

Can I reuse the sign for multiple events?

– Yes! The modular design allows easy disassembly/reassembly.

Do you offer design help?

– Free CAD file adjustments within 48 hours.

Conclusion: Why 3D Printed Signs

In an era where branding demands both aesthetic boldness and technical rigor, LEDSignsPro’s 3D printed signs deliver unparalleled value. Their fusion of aerospace-grade materials, dynamic LED controls, and SEO-ready customization positions them as the definitive choice for businesses aiming to dominate physical and digital spaces. With a 30-day risk-free trial and industry-leading warranty, hesitation is the only cost.

Call to Action: Visit LEDSignsPro’s 3D Printed Signs to request a free virtual mockup and join brands like Starbucks and Nike in the signage revolution.